Engineering Industry

Metal Finishing

This industry is a large user of ultrasonics because of the critical need for an absolute clean substrate. Whether applying organic coatings or metal deposits, the adhesion, surface, texture and general appearance of the finished product will be affected by the level of cleaning achieved. Ultrasonics has proved to be the most effective manner to aggressively dislodge and remove the most stubborn solid materials from all metal substrates without damage to even the most fragile component. In most cases, mild detergent process solution can be used instead of strong alkali and solvent cleaners.

Electroplating

Ultrasonics provides easy removal of embedded polishing compounds. It minimises the need for heavy electrolytic cleaning. Ultrasonic water rinsing after chemical processing will minimise metallic and organic contamination carry over to critical process solutions. Damaged plastisol rack coating will be rinsed completely.

Electrophoretic Coating

Complete removal of solid materials allows full metal contact with the process solution for total paint coverage.

Powder Coating

Heavy oils and solids can be removed easily using mild cleaning solutions in place of heavy alkalis. This can simplify phosphate and chromate pre-treatment’s

Aerospace

Ultrasonics cleaning effectively removes small particulate and adhering contamination from parts that have entrapment areas hard to access through mechanical means. The sound wave energy generated by transducers placed somewhere in or adjacent to an elastic medium like water, causing negative pressure, which in turn causes the liquid to fracture and cavitation to occur. The bubbles oscillate under the influence of positive pressure, grow to an unstable size, collapse and create implosions. The implosion sites cause temperatures in excess of 5,000oC and pressure in excess of 10,000PSI. At the right temperature, with the right cleaning solution and the right frequency this ultrasonic cleaning effectively removes contaminants. Agitation caused by these forces helps speed the dissolution of soluble contaminants and the displacement of insoluble particles. The cleaning effectiveness depends very much on matching the right frequency to the right cleaning task and choosing the right cleaning solutions.

Oxygen Service Cleaning

Hydrocarbons trapped in an oxygen system create the fuel that can cause an accidental fire or explosion. Factories with furnaces, autoclave systems, gold mines, aerospace facilities, refineries and gas producing plants, hospitals and even lab and test facilities all require oxygen system cleaning either at start up or after modification. Generally, oxygen system cleaning means thorough degreasing to an industry standard and in some cases removing excess rust with a caustic or a citric acid process using Ultrasonics.

Titanium Parts Cleaning

Ultrasonic precision cleaning of Titanium parts used in the medical, aerospace and other applications requires special care. Titanium parts need special care and ultrasonic cleaning is just the technology to achieve the critical cleaning required.

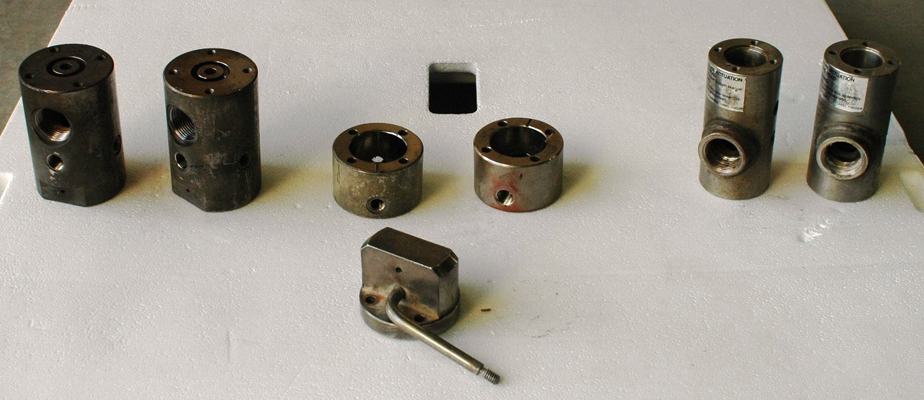

Hydraulics

Ultrasonics can easily clean any part, inside or outside, visible or non visible components with ease, precision and power. No more need for using nasty chemicals which are expensive and dangerous. No more need for spending hours upon hours trying to clean hydraulic parts.

Pumps

Finding it hard to clean hard to reach places in a pump? Not getting it as clean as you want after spending hours on it? Frustrated with your current cleaning method? Or just want something new that’s eco friendly?Industrial Ultrasonics NZ has a solution for you.

Ultrasonics is the answer to achieving an excellent clean without hassle, saving you and/or your business time and money. Industrial Ultrasonics NZ have developed a cleaning solution that is ideal for cleaning pumps internals (Even the non-visible surfaces) and externals perfectly every time.

Glue Gun Components

Electronics

It is safe cleaning electronic components in Ultrasonics. Ultrasonics has the ability to create a powerful clean, which is gentle in nature, removing all contaminants leaving the boards and components refreshed and ready for use.

Industrial Ultrasonics NZ designs and manufactures a highly efficient, easy to use and environmentally benign cleaning system developed exclusively for using with cleaning PCB stencils and related components.

Industrial Ultrasonics NZ

20 Fiesta Drive

Half Moon Bay

Manukau 2012

New Zealand

Privacy Policy

Click above for more information.